Kewei industrial robot

Kewei Robot: Assisting factories in promoting automated production with industrial robot arms.

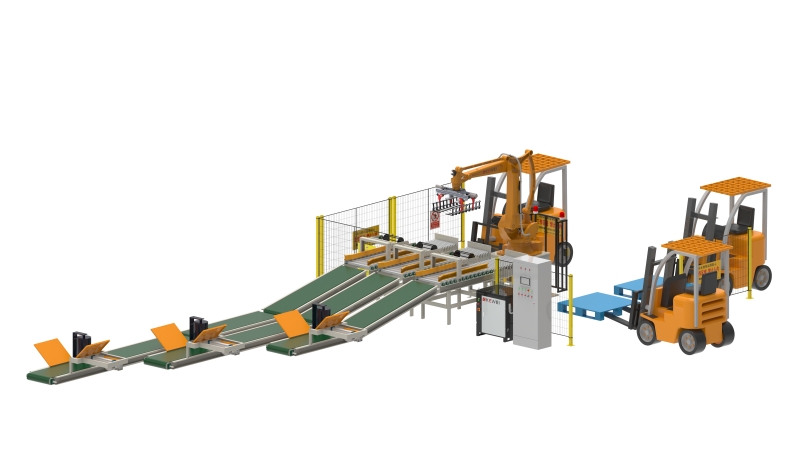

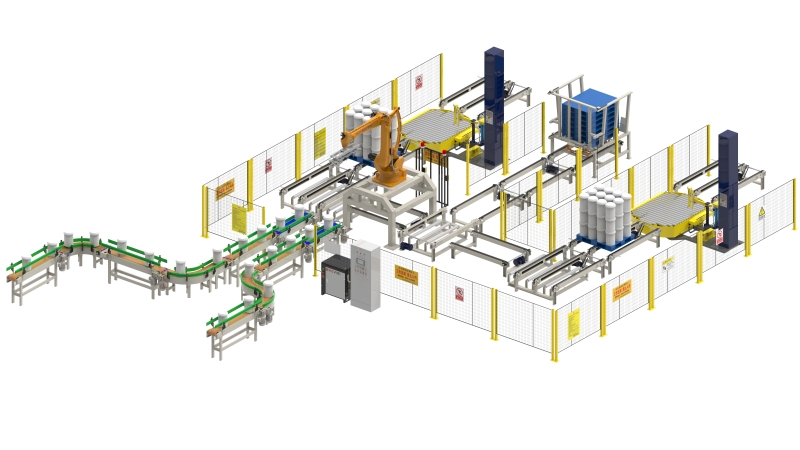

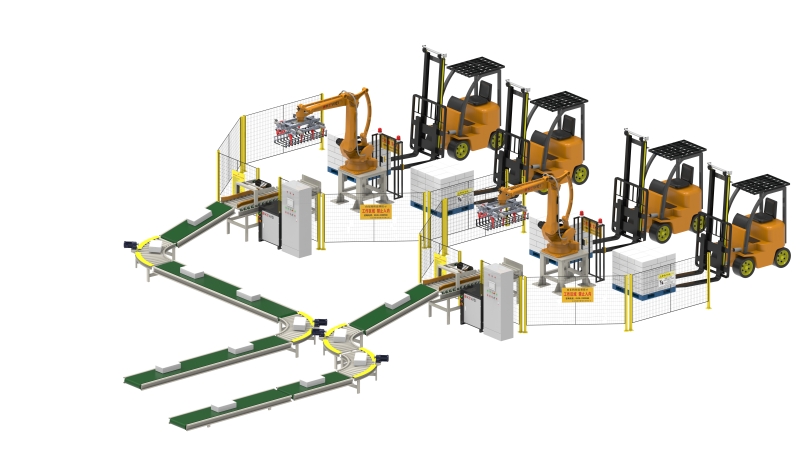

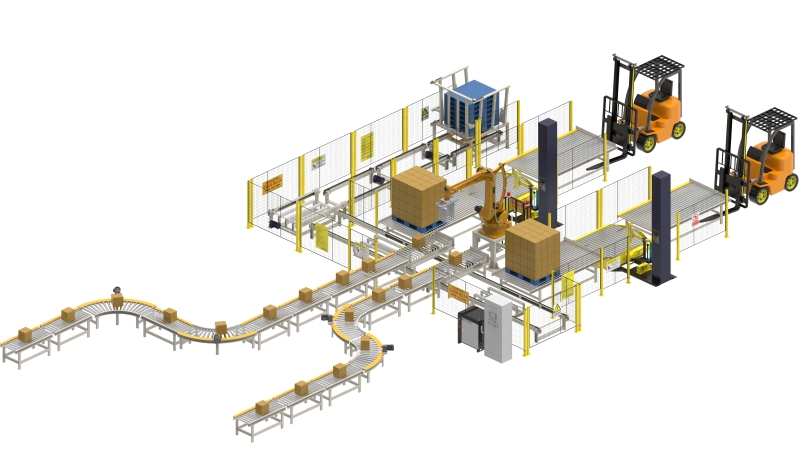

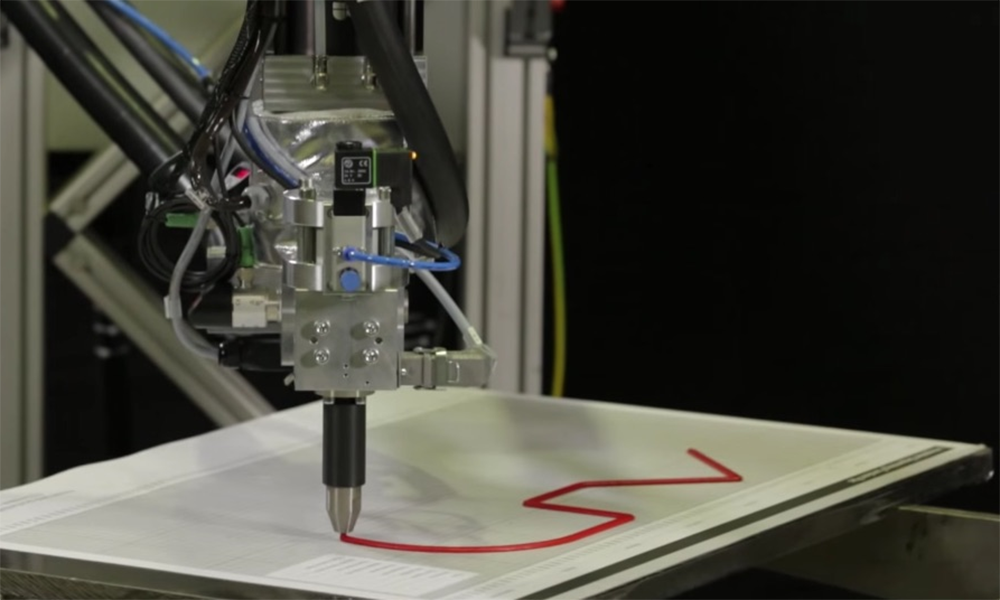

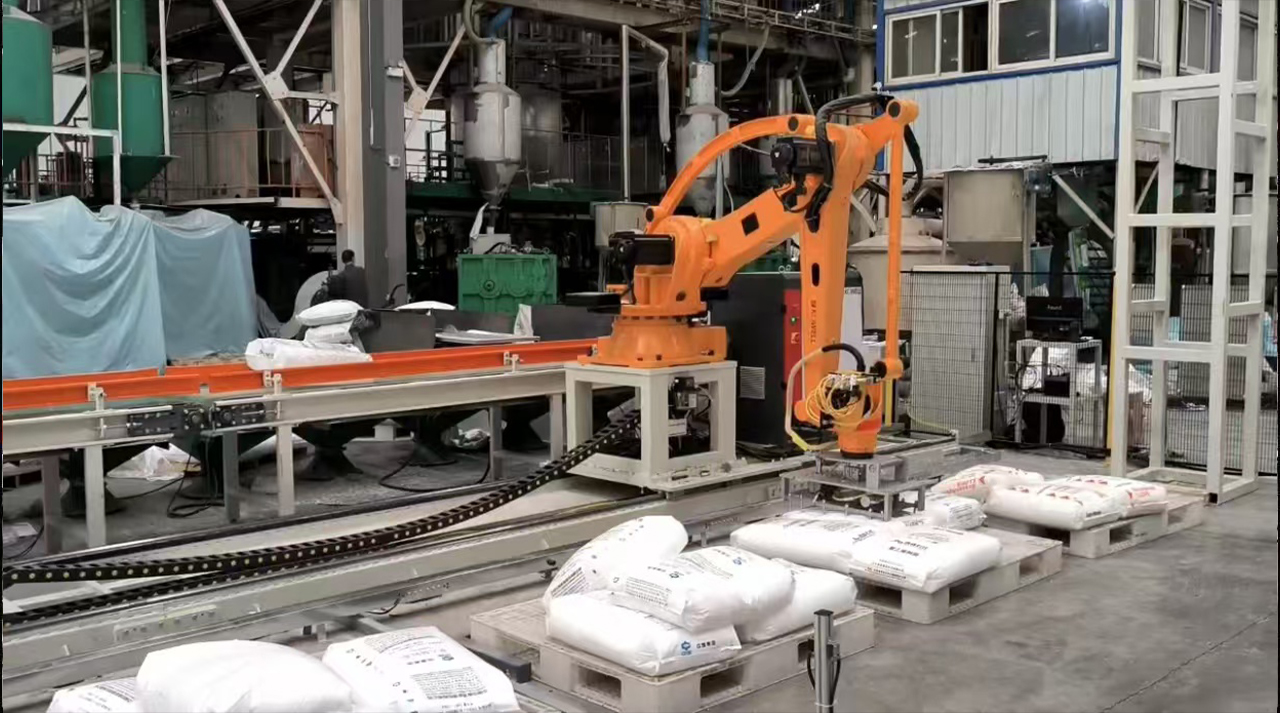

Industrial robots

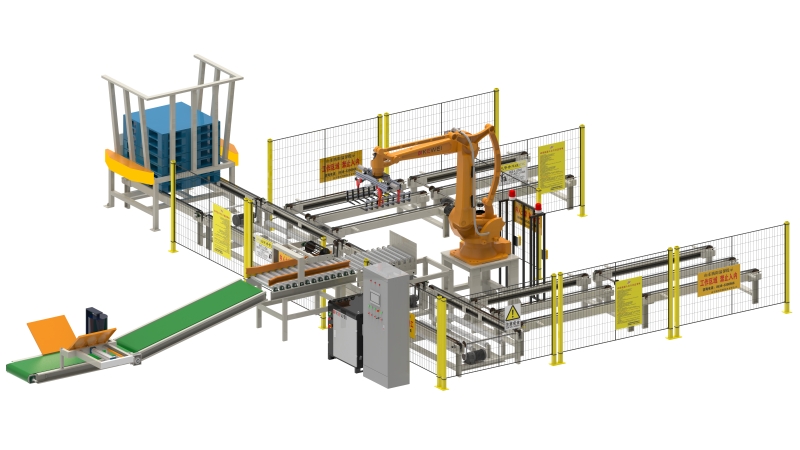

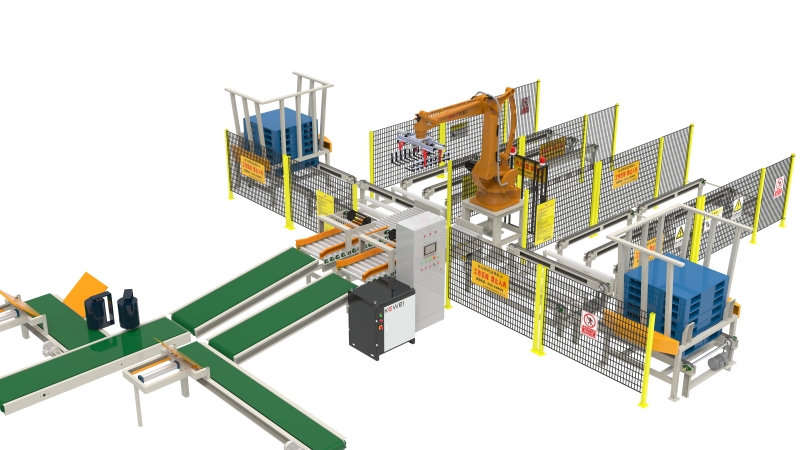

Production line

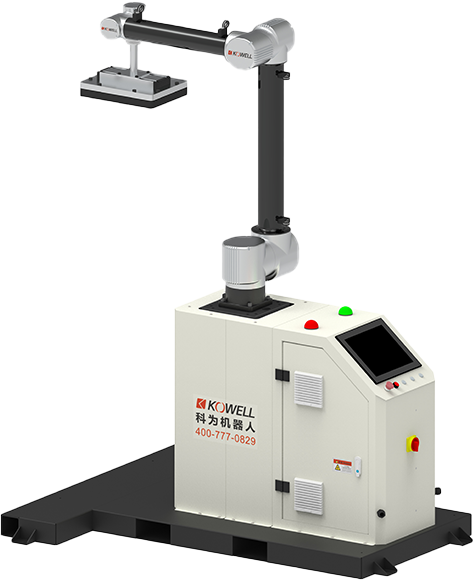

Articulated robots

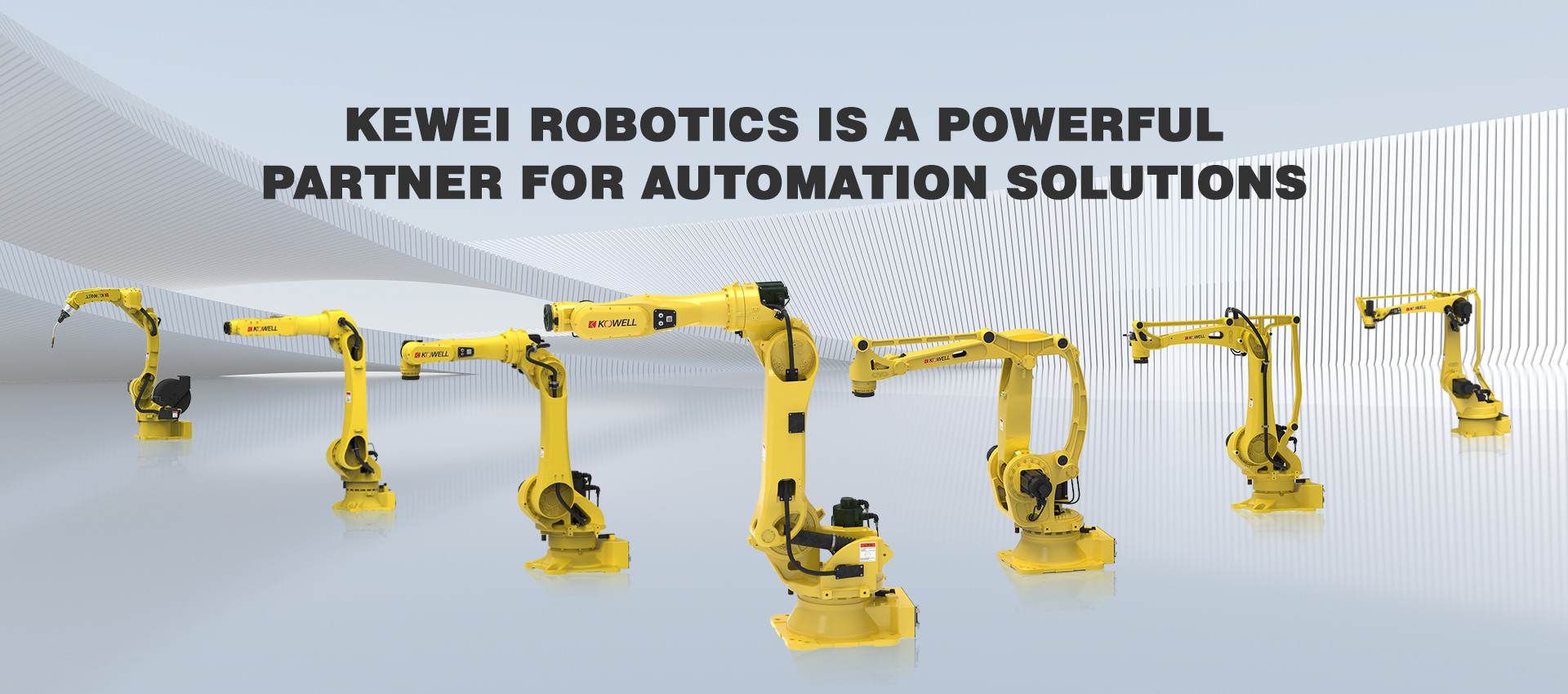

Why choose KEWEI

Kewei Robotics has successful automation experience in various industries worldwide

R&D capability

Kewei Robotics Company has 40 professional R&D personnel, 30 R&D patents and cooperates with well-known universities to jointly establish R&D centers. Significant breakthroughs have been made in the programming technology of palletizing robots.

Support 10 level collision detection

Support 10 level collision detection  Provides 16 I/O safety interfaces

Provides 16 I/O safety interfaces  Visual operation interface

Visual operation interface  Collision stop, emergency stop button

Collision stop, emergency stop button  Multifunctional scene quick switching

Multifunctional scene quick switching

Quality assurance is trustworthy

24-hour service

Source factory direct sales

Experienced global service

Shandong Kewei Robot Co., Ltd.

As a leading robot manufacturing company, Shandong Kewei Robot Co., Ltd. is committed to the research and development, manufacturing and sales of industrial robot products, providing high-quality industrial robots to global customers: robot arms with payloads of 4-800KG. Kewei has rich experience and professional knowledge in the field of robots, and has accumulated rich experience in robot welding, robot palletizing, robot picking and placing, robot stamping, and robot loading and unloading. Kewei Company has a large R&D team, consisting of a group of outstanding engineers and technical experts who are committed to continuously innovating and improving robotic technology. At the same time, Kewei also cooperates with well-known universities to jointly carry out scientific research projects and strengthen technological innovation capabilities. Kewei focuses on product quality and performance. Kewei has advanced production equipment and a strict quality control system, and strictly controls every production link to ensure product stability and reliability. At present, Kewei robot arms are widely used in food and beverage, building materials, logistics and warehousing, medical, chemical, electronics, logistics, retail and other industries. The products are exported to Turkey, Vietnam, Thailand, Malaysia and Africa, and have received the support and trust of many customers.

view more

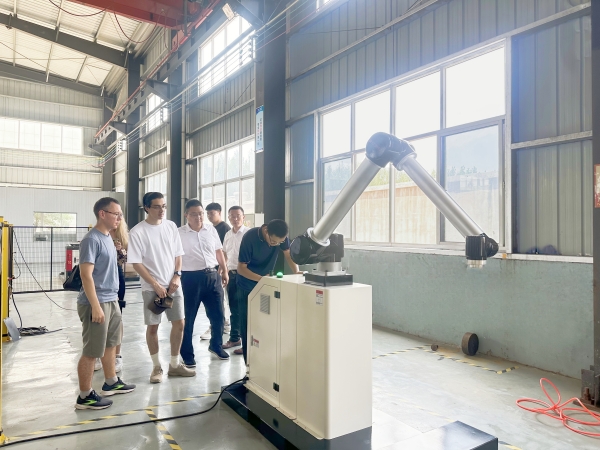

Customer visits

Insights

Exploring the Value of Industrial Robot Arms to Human Society

25-02

2026

Breaking Boundaries and Fostering Symbiosis, Leading a New Era of Intelligence | Kewei’s Intelligent Palletizing Solution Solves the Challenges of Logistics Automation

In today’s world, where digitalization and intelligentization are sweeping the globe, logis...

10-02

2026

Flexible and Boundless, Efficient and Easy to Use | Kewei Welding Robots Help Manufacturing Industry Upgrade Intelligently

As Industry 4.0 sweeps across the global manufacturing industry, and in response to the long-stan...

02-02

2026

Spatial flexibility + high rigidity and precision + high speed and convenience – how can a full range of industrial robots unlock new potential for intelligent manufacturing?

Are your production lines facing these challenges? 1.Production line changeover bottlenecks: Fac...

26-01

2026

From replacement to empowerment: How can industrial robot matrices drive a new engine for flexible and intelligent manufacturing?

Currently, the manufacturing industry stands at a critical juncture in its intelligent transforma...

21-01

2026

How does the “Precision Control and Stable Operation” intelligent loading and unloading system from Kewe Intelligent solve the challenges of intelligent stamping manufacturing?

The stamping workshop, as a critical link in manufacturing, significantly impacts a company’...

12-01

2026

From “Humans Adapting to Machines” to “Machines Adapting to Humans” | How can Kewei Collaborative Palletizing Robots help enterprises break through traditional production limitations and promote cost reduction and efficiency improvement?

Currently, the manufacturing industry is at a critical stage of transformation and upgrading. In ...Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!