With the popularization of robot technology and people's higher requirements for food hygiene quality, robotics in the food industry has shown its talents in major factories, and intelligence is spreading in every corner of the food industry. In food factories or enterprises, palletizing robots occupy a place. Palletizing robots reduce the problems of production enterprises in all aspects and improve the automation level of the entire production line.

Increasing demand for customization requires the market to transform into intelligent manufacturing models in line with the needs of the times. Modern factories need to have flexible production capabilities and use robotics in the food industry to create automation solutions to help factories achieve the goal of automated factories. Transformation and upgrading.

Robotics in the food industry is not just an efficiency tool on the production line, it is also improving food quality, reducing production costs, and ensuring food appearance rates, showing advantages that cannot be ignored. This article will explore the current application of robotics in the food industry.

Current application status of robotics in the food industry

distribution. The application of robotics in the food industry in these linkscan greatly improve production efficiency, reduce human errors, reduce the proportion of defective products, and improve the processing environment in the factory. The following are application examples in several major areas:

1.Food processing

The food processing and packaging machinery manufacturing industry is an important industry that provides technical equipment for the food industry. In the food processing process, based on the flexibility and multifunctionality of robots, robots can perform a variety of tasks, reducing the impact of pure labor on food hygiene. The replacement of pure labor by robots also correspondingly reduces the production cost of the enterprise and improves the efficiency of food hygiene. The running speed of the production line, in some aspects, is based on the templated operating characteristics of the robot, which also ensures the consistency of the product.

The food processing field is moving toward semi-automated and automated production, which is an irreversible trend.

2.Food packaging

Food packaging is one of the important links in the food industry. Robotics in the food industry is widely used in this field. Food industry robots can independently complete the entire process of food from food packaging, labeling to sealing and shipping. Robots can complete automatic stacking and packaging of products, ensuring the efficiency and consistency of the packaging process. In many modern food production workshops, in order to prevent human factors from affecting food quality, fully automatic production lines are used. Packaging robots can directly package automatically without manual participation in the entire process, which not only increases the speed of the production line, but also improves the quality of the product. Pass rate.

3.Food sorting and transportation

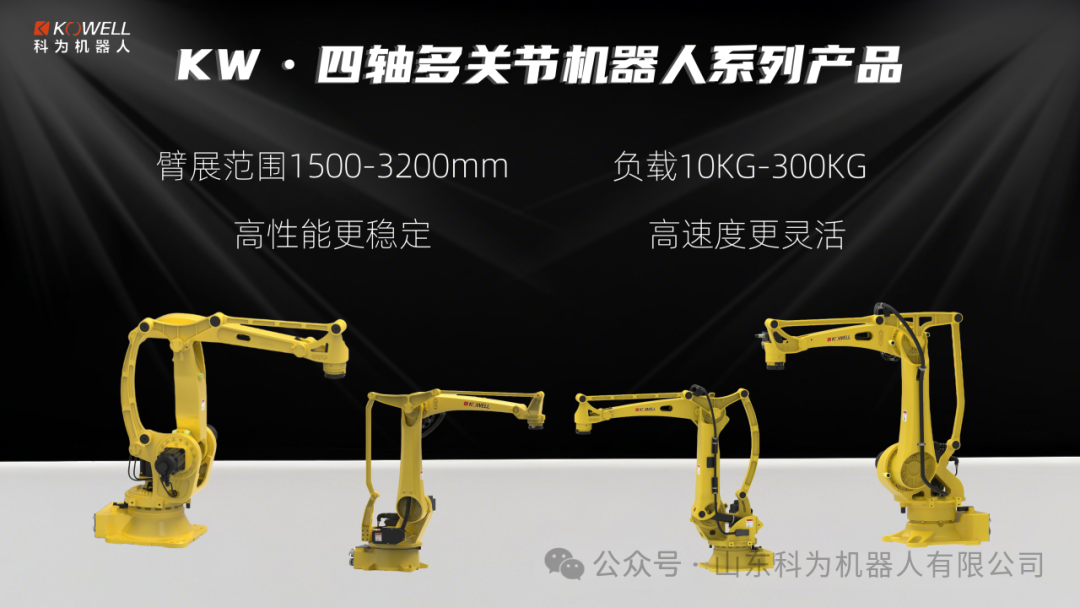

Handling and palletizing robot arms perform well in food sorting and handling, another area where robotic technology is widely used. Modern robots are generally equipped with advanced vision systems and sensors, so palletizing and handling robots can accurately and neatly stack products, and sorting robots can emotionally sort products. Based on the robot's excellent vision system, it can accurately identify products according to their shape, color, and size, reducing errors caused by human errors. Because of this, robot work improves sorting efficiency and accuracy, and robots are used for more The large range of load and movement radius can bear a weight that is far beyond the reach of manpower, further saving labor costs.

4.Food testing and quality control

Robotics in the food industry not only play a role in the production process, but are also crucial in product quality control. The robot can integrate sensors, cameras and computer vision technology to conduct high-precision testing of food surfaces, automatically identify damaged, contaminated or defective products, and automatically reject them when necessary. This testing process not only improves production efficiency but also ensures product quality and food safety.

In conclusion

Overall, robotics in the food industry has played an increasingly important role in the food industry. It not only improves production efficiency and reduces costs, but also promotes improvements in food safety and quality. Although it is still facing challenges such as high investment costs and technological adaptability, with the continuous advancement of technology and the gradual reduction of costs, robotics will have broader prospects in the food industry and will become a key force in promoting the development of the industry in the future.

Online Consultation

Hello, the current customer service is offline. You can leave your contact information and the staff will respond to you as soon as possible!

![[CIIF Day 4: Technology In-Depth] Kewei Robotics Drives Intelligent Manufacturing with Innovation, Leading the Wave of Industrial Transformation](https://cdn.cnyandex.com/kw_en/uploads/9.26.1.jpg)